Polyester Fiber Decorative Paintings: Eco-Friendly Noise Reduction Solutions in Emerging Markets

Polyester acoustic panels are made from 100% polyester fiber, formed through hot-press fusion into a cocoon shape, and processed using heat treatment methods to create breathable products with various densities. This new type of interior decoration material combines excellent performance with aesthetic appeal.

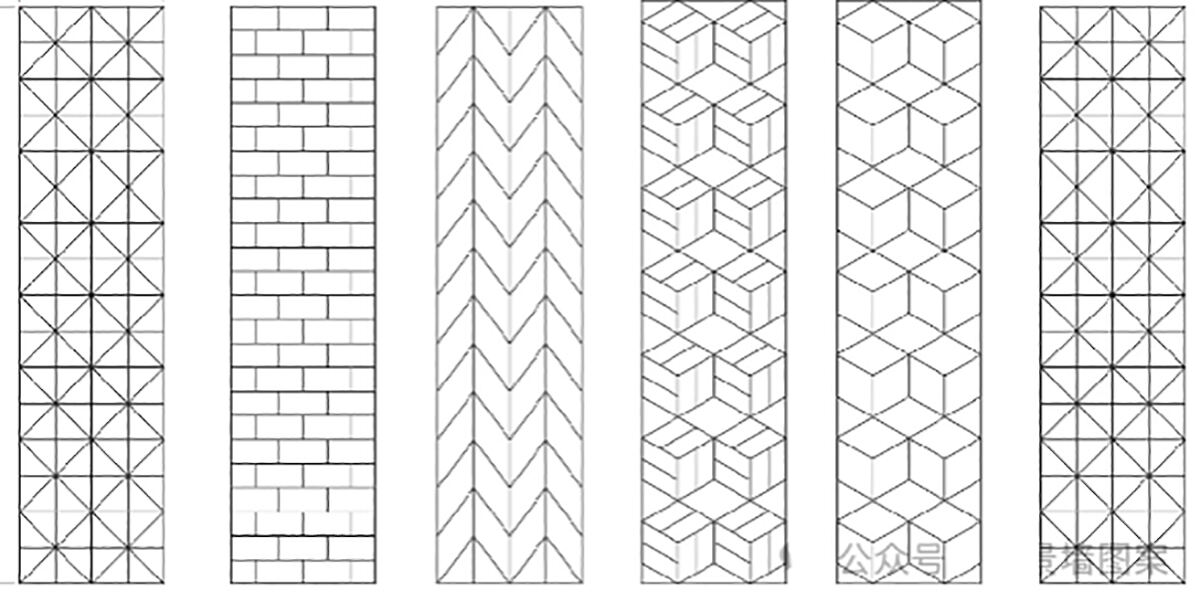

As an emerging printing technology, heat transfer allows Forest to print designs up to 2.4 meters by 1.2 meters. The standard thickness of the polyester fiber board is 6mm, and the shapes can be customized according to customer requirements. After heat transfer, the ink layer integrates seamlessly with the product's surface, greatly enhancing its overall quality.

Due to the characteristics of polyester fiber boards, traditional spray printing often struggles to address issues such as surface color variation, uniformity, and gloss. In recent years, polyester fiber decorative paintings combined with heat transfer technology have gradually become popular in the market. These decorative paintings not only offer excellent thermal insulation and energy-saving benefits but also possess low-carbon and environmentally friendly attributes. Additionally, they feature sound absorption, flame retardancy, noise reduction, and moisture resistance, making them widely applicable in venues such as cinemas, hotels, multifunctional halls, studios, recording rooms, offices, conference rooms, indoor gyms, libraries, exhibition halls, classrooms, and training centers where high sound insulation requirements are essential.

EN

EN

ONLINE

ONLINE