New and Improved Way of Making Fabric – Needle Punched Non-woven

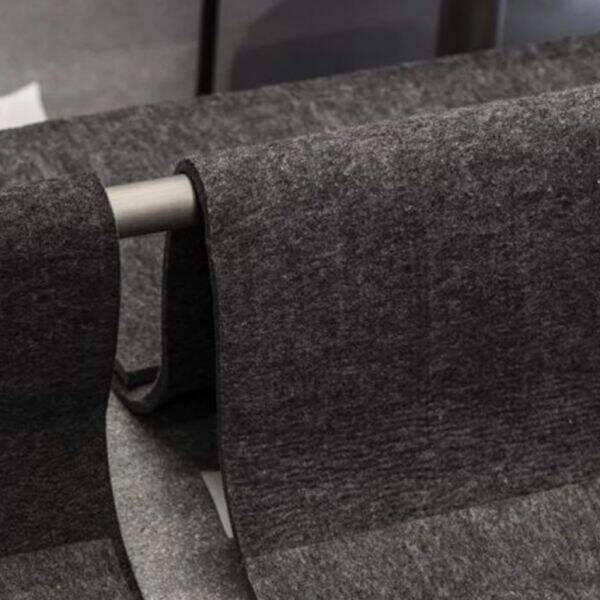

Do you know this? It's a type of created fabric by FOREST Needle Punched Non-woven together with fibers of different materials. This creates a strong fabric, versatile, and can be used for a variety of different products.

The advantages of Needle Punched Non-woven fabric are numerous. The FOREST Wooden grid is strong and durable, yet lightweight and breathable. It does not fray or ravel, making it easy to handle and work with. Due to its unique structure, it is very resistant to wear and tear. In addition to its durability, it is also easy to clean and maintain. This makes it a great choice for products that will see a lot of use, such as bags, backpacks, and furniture.

Needle Punched Non-woven fabric is a product that has been around for a while, but it is also constantly being improved upon. Innovations in the manufacturing process have made it possible to create even fabric more durable, versatile, and attractive. New FOREST Wooden Grille are continually being developed, which means that the possibilities for this type of fabric are virtually endless.

One of the most important things to consider when choosing any product is safety. Fortunately, Needle Punched Non-woven fabric is a safe choice. FOREST Wooden grating is made from Non-toxic materials and is free from harmful chemicals. This means that it can be used for a wide range of products including items that come into direct contact with the skin.

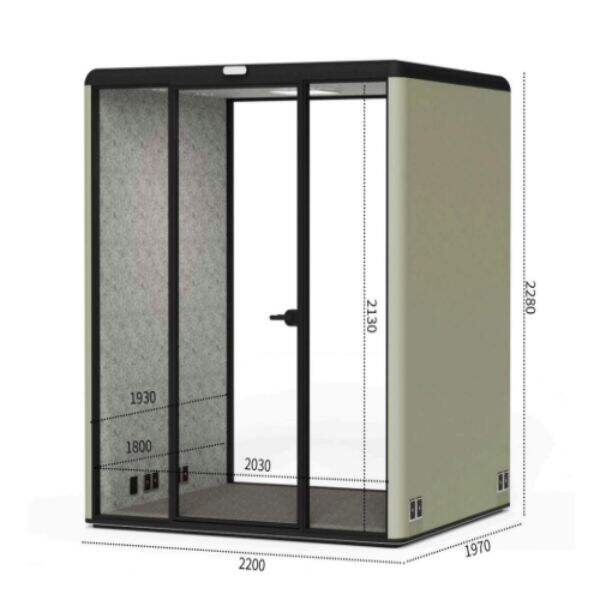

There are many different ways fabric can be used. Some of the most common uses include bags, furniture, and automotive products. The FOREST sound acoustic wall panel is also used in the manufacturing of outdoor products such as tarps and tents due to its water-resistant properties. It is also often used in clothing and bedding due to its durability and comfort.

Quality Control Department is spot-on every item is 100 100% tested before they delivered. Our after-sales department will help you Needle Punched Non-wovenissues and guarantee you satisfied. Our teamhighly qualified and professional. We also have a lot of knowledge of industry and are highly skilled.

Suzhou Forest Automobile New Material Co., Ltd.,company that Needle Punched Non-woven13,000 square meters, was founded in the year 2017. is devoted to research development, production sale of decorative automotive acoustic material. products are sold in Europe, Latin America and Africa the Middle East.

have CE, FSC, IATF16949 certifications, SGS acoustic absorption test report, SGS flame retardant formaldehyde release test report, and Global Recycling Standard certificate. The company is Needle Punched Non-wovento the principles innovation has been constantly advancing the technological advancement trend. of now, we have 27 patents on inventions. We're dedicated to providing customers with the most advanced solutions.

have a professional overseas sales team for personalized customer service. also have a team with experts in photography art and technology to help you create your products. constant effort and top-quality service have won us the trust and support from our clients. company has a Needle Punched Non-wovenreputation in the industry and is recognized a trustworthy partner.

Using Needle Punched Non-woven fabric is relatively easy. It can be cut with a pair of scissors and sewn together using a basic sewing machine. FOREST Wood sound-absorbing board is also possible to use hot glue to create a strong, permanent bond. With a wide range of colors and textures available, it is easy to create a customized both product durable and attractive.

When choosing a product like Needle Punched Non-woven fabric, FOREST noise Absorbing Panel is important to consider the level of service that comes along with it. Fortunately, many manufacturers offer a high level of customer service. They can provide details on the specifications of the fabric, assist with color choices, and help with any technical questions. This can ensure that the final product meets all of the customer's needs and expectations.

Finally, quality is a crucial consideration when choosing any product. Fortunately, Needle Punched Non-woven fabric is known for its high quality. The manufacturing process is carefully controlled to ensure that the fabric has a consistent look and feel. The FOREST interior acoustic panel are chosen for their strength and durability, ensuring that the final product will stand up to heavy use. In addition, each manufacturer uses a unique process that results in a fabric with its own unique characteristics.

ONLINE

ONLINE